Filling bulk bags efficiently and reliably can be a tough task without the right equipment. The frustration of delays, wasted resources, and inconsistent results can quickly add up, especially during emergencies or large-scale projects. This is where a bulk bag filler steps in as a game-changer.

This blog dives into the features of our bulk bag filling machines, explaining how they address common challenges in handling and packaging bulk materials. We’ll walk you through how our machines operate and why they’re vital for improving productivity, consistency, and overall efficiency across various applications.

Common Bulk Filling Issues

Filling bulk materials by hand or with outdated methods can lead to several frustrating challenges that slow down operations and drive up costs. These issues not only make the process time-consuming but also impact the quality and consistency of the output. Let’s explore some of the common obstacles and the complications they bring to bulk bag filling.

- Time-Intensive Processes: Without specialized equipment, each bag takes significantly longer to fill, making it hard to keep up with production demands, especially for large projects.

- Increased Labor Costs: Manual filling requires more hands-on work, which can mean hiring more workers and higher labor expenses, all while risking burnout and inefficiency.

- Material Spillage and Waste: Handling bulk materials manually often leads to spillage, wasting valuable resources and creating a mess that requires additional cleanup time.

- Physical Strain on Workers: Repeated lifting and handling of heavy materials can lead to worker fatigue, injuries, and increased downtime, making the process not only slow but also unsafe.

These problems show why a dependable machine is needed to make bulk filling easier, and more accurate.

What Our Bulk Bagging Machine Can Do

Our bulk bagging machine is designed to efficiently package large quantities of materials into bulk bags. It is a flexible solution for industries that need to handle materials like sand, gravel, powders, or grains in bulk.

The machine works by transferring the material into large bags, allowing for consistent and controlled filling. It is ideal for businesses that require high-volume packaging without the complexity of fully automated systems, offering a simple yet effective way to manage bulk material handling.

How Our Bulk Bag Filling Machines Operate

Our bulk bag filling machine simplifies the process of handling and packaging bulk materials. Its design ensures you can efficiently manage large-scale operations without needing complex automated systems. Here’s a detailed breakdown of how the process works:

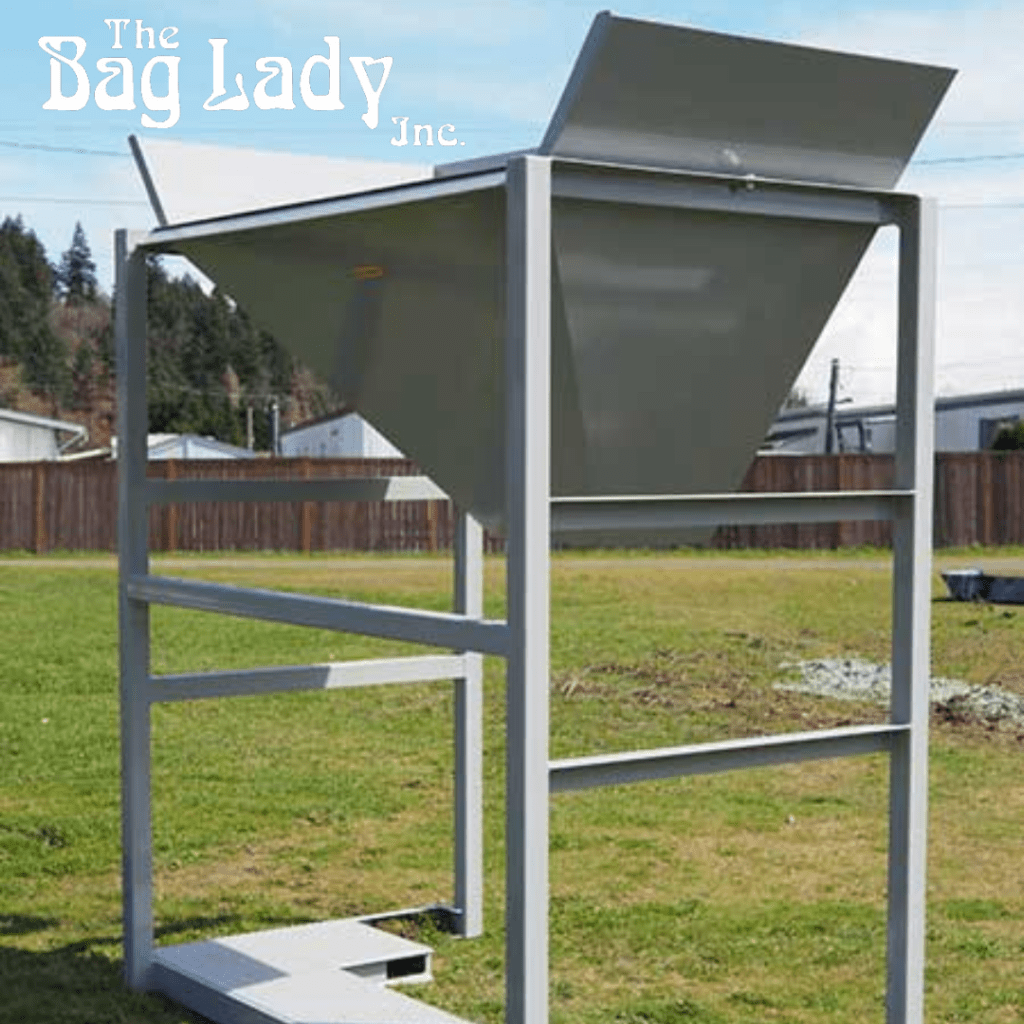

- Filling the Funnel with Material: At the core of our machine is a large funnel that serves as the primary container for materials. Operators use forklifts, or equipment similar to bulldozers, to dump materials—such as sand, gravel, or other bulk goods—directly into the funnel. This ensures a consistent supply of material to start the process.

- Positioning the Bulk Bag: The operator places the bulk bag beneath the funnel’s spout. The spout is designed to direct materials into the bag with precision, minimizing waste and spillage. Adjustments are made to align the bag properly, ensuring it stays steady as filling begins.

- Controlled Filling Process: The material flows from the funnel into the bulk bag. This manual approach ensures accuracy, particularly when working with varying material types or bag sizes.

- Completing the Process: Once the desired weight or volume is achieved, the operator secures the filled bag. Forklifts are then used to lift and transport the bulk bag for storage, shipment, or further handling. This seamless transition ensures that the filled bags are ready for the next step without unnecessary delays or complications.

Benefits of Using Our Bulk Bagging Machines

Employing bulk bagging machines offers numerous advantages that enhance production efficiency and overall operations. Understanding these benefits can help businesses make informed decisions regarding their packaging processes. The right choice in machinery, particularly quality bulk bag-filling equipment, can lead to significant improvements.

- Increased Efficiency: Bulk bagging machines streamline the filling process, allowing for faster packaging compared to manual methods. This increased speed leads to higher throughput, helping businesses meet production targets more effectively.

- Versatility: Bulk bagging machines can handle a wide variety of materials, from powders to granules, making them suitable for various industries. This versatility allows businesses to adapt quickly to changing market demands or product lines.

- Consistent Quality: These machines help maintain consistent quality in packaging by standardizing the bulk bag-filling process. This uniformity is crucial for businesses that prioritize high standards and customer satisfaction.

For all your bulk bag-filling needs, The Bag Lady is a trusted leader in the industry. With years of experience and a deep understanding of the challenges businesses face, we have established ourselves as the go-to supplier for companies looking to improve efficiency and streamline their sandbagging processes. Our solutions are designed to help you increase productivity, and ensure consistent, high-quality results.

Applications of Bulk Bagging Machines

Bulk bagging machines are versatile tools utilized across various industries, catering to the specific packaging needs of different materials. Their ability to efficiently handle large volumes of products makes them an invaluable asset in numerous sectors.

Understanding the applications of these machines can help businesses recognize their potential benefits and identify areas where they can improve operational efficiency.

- Agriculture: Bulk bagging machines are used in the agricultural sector to package fertilizers, seeds, and grains. They ensure that these products are stored securely and can be transported easily, minimizing the risk of spoilage or contamination.

- Construction Materials: Bulk bagging machines are employed in the construction industry for packaging materials like sand, gravel, and cement. Their efficiency in handling heavy materials streamlines the loading and transportation process.

- Plastics and Resins: These machines play a significant role in the plastics industry, packaging resins, pellets, and compounds. Their ability to handle various material types makes them essential for manufacturers looking to optimize their operations.

Maintenance and Care for Bulk Bagging Machines

Proper maintenance and care of bulk bagging machines are crucial for ensuring their longevity and optimal performance. Regular inspections should be conducted to identify any wear and tear. Regular cleaning of the machine after use helps prevent material buildup, ensuring smooth operation and minimizing the risk of contamination.

Maintaining a log can help track any repairs or replacements, providing valuable information for future servicing. Overall, a proactive approach to maintenance enhances the machine’s performance and reduces the risk of unexpected downtime, ensuring consistent productivity in bulk bagging operations.

Choosing The Bag Lady For Your Needs

Selecting the right bulk bagging machine is crucial for ensuring that your sandbagging operations run smoothly and efficiently. At The Bag Lady, we offer reliable machines designed to meet a variety of needs, ensuring you get the right fit for your production demands. Choosing the right equipment can make a significant difference in maximizing productivity and reducing downtime, which is why it’s important to carefully consider all your options.

- Easy to Use: Our bulk bagging machines are designed with user-friendliness in mind, allowing for quick setup and operation. This ease of use ensures that your team can get up and running with minimal training, improving overall efficiency and reducing operational errors.

- Built Tough: Durability is essential in any industrial setting. The Bag Lady’s machines are built tough to withstand heavy-duty use and offer long-lasting performance, even in the most demanding environments.

- Portable: The portability of our machines provides you with flexibility, allowing easy relocation and use in different areas of your facility. Whether you need to move the equipment for different projects or reconfigure your workspace, portability ensures that you can make the most of your investment.

We offer complete, ready-to-use solutions that include everything you need to get started immediately. In addition to our standard machines, we also offer automated bulk bag filling options for higher volume needs, streamlining the process and enhancing productivity.

Whether you’re filling sandbags, aggregates, or any other material, our equipment can be adapted to suit whatever your specific needs may be. We have reliable machines to optimize your operations and provide a solution that works for you. Contact The Bag Lady today to discover how our advanced technology can enhance your business and take your operations to the next level.